HDPE Large Diameter Water Supply Gas Pipe Production Line 1. Equipment performance and advantages:The HDPE/MDPE water supply pipe and gas pipe production line developed by our company has unique structure, high degree of automation, convenient operation, stable and reliable continuous production.Composition: The production line consists of a control system, an extruder, a die head, a shaping cooling system, a tractor, a planetary cutting device and a turning frame.Die and auxiliary machine: The machine head adopts the newly designed basket head or the spiral split-flow extrusion tube compound head, which has the characteristics of easy adjustment and uniform discharge. The sizing sleeve adopts a unique grooving process and water ring cooling to ensure The forming accuracy of the pipe. It adopts the control system composed of advanced PLC and color large-screen liquid crystal display screen. It has a perfect alarm system and a good Chinese man-machine interface, and the operation is very convenient. 2. Extruder technical parameters Production line modelPipe specification mmextruderMaximum output (kg/h)Total installed power (KW)Production line length (m)PE-32Φ4-32SJ-45/3030-1204528PE-63Φ20-63SJ-60/33120-22010036PE-110Φ20-110SJ-65/33150-25012039PE-160Φ63-160SJ-65/33120-27015043PE-250Φ75-250SJ-75/33280-40023045PE-450Φ110-450SJ-90/33450-60035065PE-630Φ315-630SJ-120/33700-95055075PE-800Φ400-800SJ-150/33800-120070075 Tractor technical parameters modelQY250/3QY315/3QY400/4QY630/6QY800/6Traction diameter rangeΦ75-Φ200Φ250-Φ315Φ280-Φ400Φ355-Φ630Φ560-Φ800Number of tracks34466Traction effective length13401340180018001800Driving power (KW)345.57.57.5…

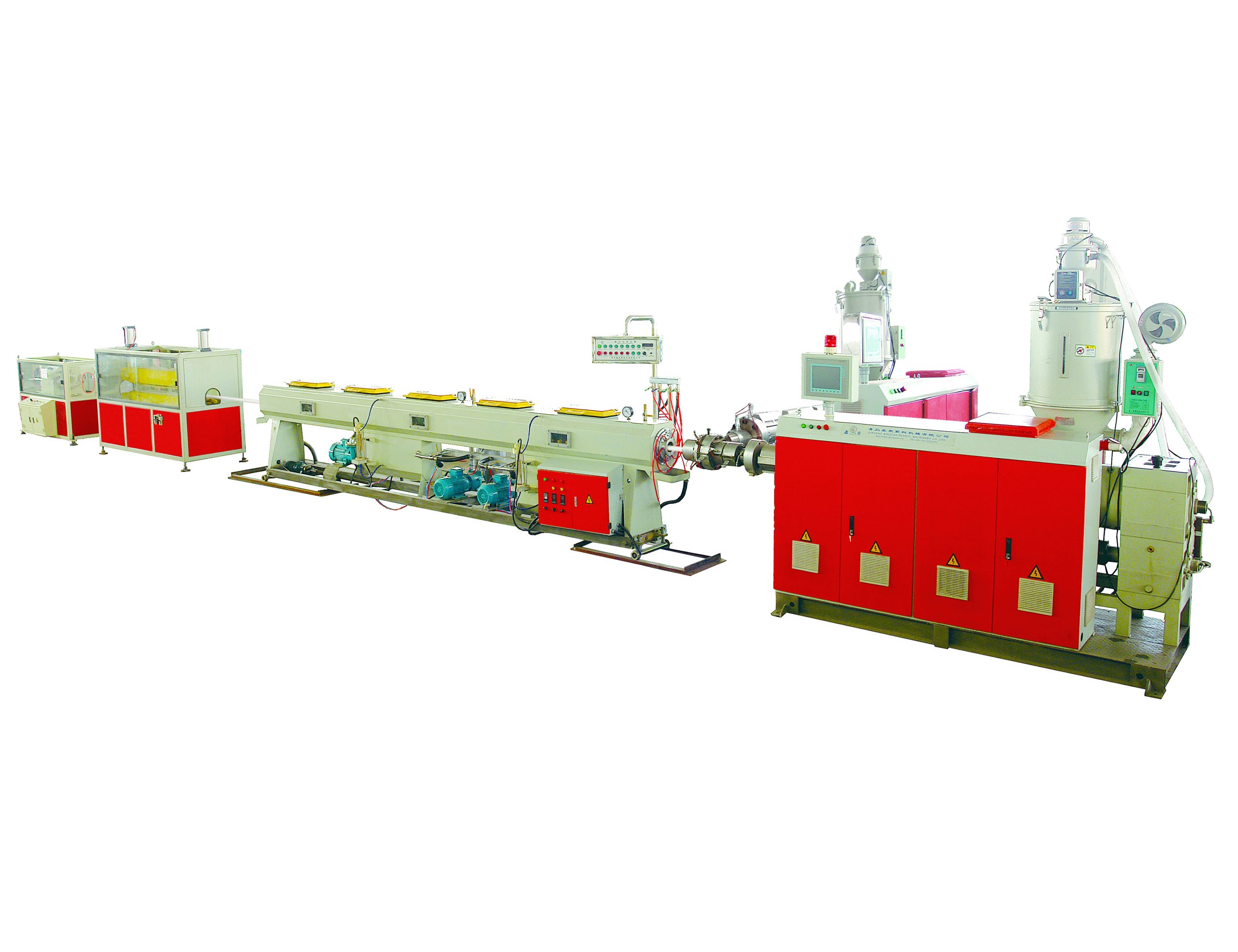

Plastic pipe production line 1. Features of the plastic pipe production line produced by Xinquan Plastic Machine: The plastic pipe production line produced by Xinquan Plastic Machinery consists of a conical (parallel) twin-screw extruder, a vacuum setting table, a tractor, a cutting machine, a turning frame, etc. The screw extruder and traction machine adopt imported AC frequency conversion speed regulation device, and the screw barrel is chrome-plated with bimetal, which effectively reduces the wear of the extruder after the addition of calcium carbonate and various additives; the vacuum pump and traction motor are made of high-quality product.The traction machine has two-claw, three-claw, four-claw, six-claw, eight-claw and other traction methods. Saw blade cutting type or planetary cutting type can be selected, and a length counter and thickening device are also provided. The unit has reliable performance and high production efficiency. According to the requirements of users, the company can replace the extruder with special equipment to produce inner wall spiral tube, inner wall hollow tube and core layer foam tube unit, and can produce PP, PE, ABS, PP-R, PEX, silicon core tube, etc. Other material…

Inner insert type drip irrigation pipe production line The production line adopts PCC integrated control system to control the whole line synchronously. SIMENS digitally integrated Ethernet distributed PCC master control technology. The system can be remotely controlled through terminal devices such as computers and mobile phones, such as timing startup, fault diagnosis, recipe download, and can view the operating instructions in the built-in system at any time;Adopt automatic double station coiler, Siemens programmable PLC independent control, command setting entry; imported motor drive, adjustable wire pitch; it has the functions of automatic cutting of pipes and automatic switching of reels during operation, which does not affect the continuity of pipes. High-speed production; equipped with a tension control device, which is precisely synchronized with the pipe production;The dripper automatic screening and conveying device adopts intelligent measurement and control technology - nanosecond laser recognition device, reverse dripper automatic rejection device, two-level insurance automatic measurement and control device, with dripper broken, error alarm system;The vacuum sizing box and cooling water tank are made of brushed stainless steel. The high-performance PLC system automatically and accurately controls the…

PVC water supply and drainage pipes:1. Features of PVC water supply and drainage pipes: It has excellent chemical resistance and insulation; the product size is standard and stable, the material is dense, and the wall thickness is uniform; pressure resistance, flame retardant, high strength; smooth pipe wall, low friction resistance, no scaling, efficient transportation; durable, The service life is 20 to 50 years; it is widely used in agricultural water supply and drainage, building water supply and drainage, cable laying, etc. 2. Features of the production line: The unit consists of a conical (parallel) twin-screw extruder, a vacuum setting table, a tractor, a cutting machine, a turning frame, etc. The screw extruder and traction machine adopt imported AC frequency conversion speed regulation device, and the screw barrel is chrome-plated with bimetal, which effectively reduces the wear of the extruder after the addition of calcium carbonate and various additives; the vacuum pump and traction motor are made of high-quality product. The traction machine has two-claw, three-claw, four-claw, six-claw, eight-claw and other traction methods. Saw blade cutting type or planetary cutting type can be…

HDPE high density polyethylene silicon core pipe production line 1. Features of silicon core tube production line: Equipped with a special mixing screw to ensure high-speed and high-performance extrusion; the sizing sleeve adopts a disc-type sizing with a water curtain at the entrance, and the production speed is up to 16 m/min; the specially designed die head can effectively reduce the thickness of the silicon core layer, Cost saving; one machine is multi-purpose, replacing the die head can produce ordinary PP-R, PE, PEX pipes. 2. Pipe performance characteristics: Widely used in optical cable communication network systems; the silicon core layer on the inner wall is a solid, permanent lubricant; the silicon core layer on the inner wall is synchronously extruded into the HDPE pipe wall and evenly distributed throughout the pipe The inner wall will not peel off or fall off, and has the same life as the silicon tube.

1. The main motor, forming machine and traction machine are all controlled by frequency conversion speed regulation, which is energy-saving, stable in operation and low in noise. 2. The tube blank diameter measurement adopts CCD chip and MCU micro-processing chip, which is controlled by PWM signal, with fast speed, high reliability and stable control. 3. The forming wheel is made of high-quality stainless steel, which is corrosion-resistant and has a long service life.

Inlaid cylindrical drip irrigation pipe production line The head mold is specially optimized and designed; it combines the necessary elements for high-speed and stable production of plastic pipes such as precise inlay, traction unit, and automatic punching; The centrifugal screening device is used to screen and sort the drippers, which has many optimization elements such as high screening accuracy, sorting speed block, and high dripper recognition speed, which can ensure the accurate supply of drippers during high-speed production; The dripper is embedded with a push rod, the embedding speed is fast, and the dripper spacing can be automatically adjusted when producing products of different specifications, which ensures the accuracy of the dripper spacing at different line speeds; The mechanical punching method is adopted to automatically track the production speed of the pipe to ensure the accurate punching position; Dripper feeding, screening and sorting, conveying and embedding, traction, punching, coiling series production process synchronous control, to ensure precise synchronous control and stable operation during high-speed production; The products are widely used in many water-saving irrigation fields such as greenhouses, landscaping projects, farmland planting,…

PPR, PP, PE Single Layer or Multi-layer Pipe Co-extrusion Production Line 1. PP-R, PP, PE single-layer or multi-layer water supply pipe features: In current construction and installation projects, PE, PP, PPR pipes (pieces) are mostly used for heating and water supply. Its advantages are convenient and quick installation, economical, environmentally friendly, light weight, hygienic and non-toxic, good heat resistance, corrosion resistance, good thermal insulation performance, long life and so on. 2. About the production line: The extruder is controlled by PLC or temperature control instrument, the temperature control is accurate, and the plasticizing quality is effectively guaranteed; the special screw design ensures high efficiency and high output; the helical gear design with high hardness and low noise brings reliable and stable extrusion performance and long service life. The diverter of the pipe die adopts spiral distribution type or blue type diverter. The large flow space ensures sufficient residence time of the melt; the internal stress in the pipe is small, and the inner and outer surfaces are smooth; the die design has high flexibility and is suitable for co-extrusion of all polyolefin…

HDPE large diameter hollow wall winding pipe (underground sewage pipe) production line 1. Features of the production line: The main machine of the production line adopts a double-stage decompression screw with special components for promoting mixing and plasticizing. With the cooperation of high torque and high temperature control accuracy, it is guaranteed that all recycled materials can be used for production. Two-machine combined feeding, spiral rotation molding, and efficient compounding process ensure high product quality. Using special plastic-steel compounding technology, the pipe material is compounded reliably and the performance of the pipe material is enhanced. Using an adjustable extrusion frame, the operation is convenient and flexible. Adopt PLC automatic control system, reliable performance and easy maintenance. 2. Pipe features: The pipe ring has high rigidity, light weight and low cost; good interface sealing performance; acid and alkali resistance, no corrosion, long service life and convenient construction. Application areas: urban buried drainage, sewage pipes. 3. Main technical parameters: model Pipe diameter (mm) Maximum output (kg/h) Dimensions (LXWXH)(m) SG-800 Φ200-800 280 8X20X2.6 SG-1200 Φ600-1200 500 10X23X2.7 SG-1500 Φ1000-1500 600 28X18X6 SG-2000 Φ1500-2000 700 30X20X7 SG-3000 Φ2000-3000 800 32X20X8

PVC, PE single-wall corrugated pipe production line 1. Pipe product advantages and applications: PP, PE, PVC Single Wall Corrugated Dryer has high temperature resistance, corrosion resistance, abrasion resistance and high strength. It is used in electrical conduits, automobile conduits, sheath tubes, machine tool products, packaging food machinery, electric locomotives, engineering installations, lamps, automated instruments and other fields, and the market demand is large. Temperature range of PP material pipe: - 20℃-110℃ Oil, acid and alkali resistant black pipe UV resistant PE material pipe temperature range: - 40℃-80℃ Oil, acid and alkali resistant black pipe UV resistant PVC material pipe temperature range - 10℃-95℃ acid and alkali resistant black tube UV resistant 2. Equipment performance and advantages: The structure design of special screw and mold is reasonable, and the replacement of mold is convenient and reliable, which solves the problems of easy wear and tear of screw barrel and difficult material forming. The metering meter is accurate; the entire production line runs stably, and the control is simple and easy to operate. 3. Main technical parameters Device model DBG-63 DBG-75 DBG-160 DBG-10…

PE carbon spiral reinforced pipe production line 1. Features of the production line Equipped with a special single-screw extruder for polyolefin, which has the characteristics of high-speed extrusion, high-speed acceleration, etc.; specially designed sizing cooling method: production range 50-200mm; the best design for low melting temperature, the internal stress of the pipe is small, and the internal and external Smooth surface; high flexibility, suitable for co-extrusion of all polyolefin materials, can extrude two-layer, three-layer spiral reinforced pipes with different specifications; the inlet end of the optimized copper spiral sizing sleeve has a pre-cooling device And strong suction and vacuum device, suitable for high-speed extrusion of the pipe; longitudinal movement motor adjustment, three-dimensional adjustment can be achieved up, down, left and right; high-efficiency water pump and special sprinkler head bring efficient spray cooling. 2. Features of PE carbon tube: The PE carbon tube product has a special thread shape, which can be bent freely to bypass obstacles, which is convenient for construction. The length of a single PE carbon tube is determined by the user at will, so as to reduce the…

UPVC double pipe production line 1. Features of UPVC double pipe extrusion line: The products produced by the UPVC double-pipe extrusion production line are mainly used in construction threading pipes, electrical pipes, etc. The first-class quality has been integrated into many years of experience. The main machine adopts a conical twin-screw extruder to improve the mixing effect and the extrusion pressure is high. Double tube extrusion die. High production efficiency and stable molding. Using double-tube vacuum sizing technology, spray cooling to ensure the quality of the tube. Independent control of the overall structure of the double-tube pulling mechanism and synchronous cutting device. The equipment is compact and occupies a small area. 2. Main technical parameters: model SJSZ51/105 Applicable raw materials pvc Extruder Model SJSZ51/105 Diameter range mm 16-50 Motor Power 22kw Maximum extrusion volume 120kg/h Production speedm/min 3-10

PVC Fiber Reinforced Hose Production Line 1. Pipe features and uses: PVC fiber reinforced hose, also known as PVC mesh pipe, commonly known as plastic snakeskin pipe, the hose has many characteristics such as non-toxic, transparent, pressure resistance, stretch resistance, acid and alkali resistance, beautiful appearance, soft and lightweight, durable and so on. It is suitable for the transportation of pressurized or corrosive gases and liquids, and is widely used in machinery, coal mines, petroleum, chemical industry, agricultural irrigation, construction, civil use (solar water heaters, gas tanks) and other fields. It is also widely used in the watering of gardens and lawns. 2. Production line The PVC fiber reinforced hose production line is mainly composed of extruder spray tank, tractor, winding machine, coiler, etc. It has the characteristics of reasonable matching, unique structure, reliable performance, simple operation, convenient maintenance, strong continuous production capacity, etc., and is deeply welcomed and trusted by the majority of users.

UPVC foam inner spiral muffler pipe production line 1. Pipe features and applications: For building drainage pipes. The unique internal helical structure makes the water flow down along the thread, which greatly reduces the noise caused by the water flow. 2. Equipment structure: The main machine adopts the co-extrusion of two twin-screw extruders, and the advanced process formula obtained by many years of practice and experience. The co-extrusion die head can be specially designed, and the solid wall tube, the solid wall inner spiral tube, the foamed tube and the foamed inner spiral tube can be produced at the same time only by changing the mandrel. Replacing the mold can produce nano-antibacterial PVC water supply pipe, hollow wall inner spiral muffler pipe. 3. Technical parameters: Host model: SJSZ-65/22 SJ-SZ-55/22 Production pipe range mm: ∮16-∮160 Production speed: 1-12 m/min

PVC steel wire reinforced hose production line 1. Introduction of production line High-speed and high-efficiency extruder is used to ensure material plasticization quality and output. The specially designed wire spring winding machine has uniform winding spring and long continuous production time. The pipe produced by the specially designed pipe head has high transparency, uniform distribution of steel wires, and the length can be set arbitrarily. The main electrical components of the unit are imported products, and the operation is stable and reliable. All control buttons of the unit are designed in one piece, which is easy and quick to operate. 2. Main technical parameters model XQS45 XQS65 XQS90 SQS120 extruder SJ45/30 SJ65/30 SJ90/30 SJ120/30 Specification range ф12-25 Ф20-50 Ф50-102 Ф75-150 Yield 20-40 40-75 70-130 100-150 Installed power 30 40 50 75

Small diameter hose, medical tube production line This unit is mainly used to produce PVC, PP, PE and other plastic hoses, which can be widely used in medical, chemical, beverage and other industries. Production hose varieties: single tube, single tube with color code, equal-diameter parallel tube, different diameter parallel tube, color-coded parallel tube…. The design of this unit is advanced, the main engine and the marking machine adopt frequency conversion speed regulation, and the extrusion speed is stable. Water level and water temperature control of cooling water tank. Host model: ST-45×25 stainless steel water tank, length 2 meters, with drying device; non-toxic plastic flat belt tractor, power: 0.06kw×2 double station coiler, power: 0.75kw.